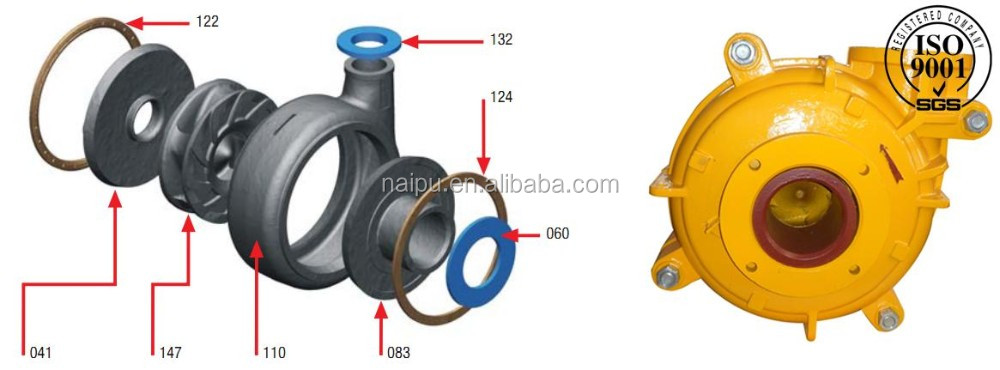

1. Slurry pump impeller introduction

The Impeller is one of the most important parts of slurry pump. Centrifugal pumps need impeller to

produce the centrifugal force which transfer the slurries. The centrifugal force is produced by the

impeller which rotates to a certain speed.

We offers two solutions for the problem of long service life. We choose the white iron, high chrome (27%) for the strong abrasive slurries with sharp particles. For the corrosive slurries with blunt particles, we recommend the natural rubber.

1. Widely application: Designed for handling abrasive, high density slurries in the metallurgical, mining,coal, power, building material and other industrial departments.

2. Anti-abrasion wet parts: The wet parts can be made of pressure molded rubber. They are completely interchangeable with metal wet parts.

3. Easy adjustment of impeller: An impeller adjustment mechanism is provided below the bearing housing.

2.Material of our impellers and other wet end parts:

High chrome alloy: A05, A07, A49, etc.

Natural rubber: R08, R26, R33, R55, etc.

Other material as per requests, like stainless steel, duplex stainless steel, Nickle alloy, Alloy 20, etc.

|

|

Name

|

Material

|

|

1

|

Impeller

|

High-chrome alloy

|

|

Natural Rubber

|

|

2

|

Volute casing

|

High-chrome alloy

|

|

3

|

Front liner plate

|

High-chrome alloy

|

|

Natural Rubber

|

|

4

|

Rear liner plate

|

High-chrome alloy

|

|

Natural Rubber

|

|

5

|

Liner

|

High-chrome alloy

|

|

6

|

Expeller

|

High-chrome alloy

|

|

7

|

Shaft sleeve

|

3Cr13

|

|

8

|

Water-seal ring

|

High-chrome alloy

|

|

9

|

Shaft

|

45#steel quenching And high temperature tempering

|

|

10

|

Bearing housing

|

Gray iron

|

|

11

|

Expeller ring

|

High-chrome alloy

|

|

Natural Rubber

|

|

12

|

Front casing

|

Gray iron or Nodular cast iron

|

|

13

|

Rear casing

|

Gray iron or Nodular cast iron

|

|

14

|

Base

|

Gray iron

|

|

15

|

Support

|

QT500-7

|